DESCRIPTION

Discover innovation in mining communication with our informative LED displays, leaders in effective and real-time monitoring for committed workers. Designed to inform about adverse conditions and potential risks in the mine, these displays adapt and update instantly according to ongoing operations. Our LED display has a clear purpose: to improve safety and prevent risks in every corner of the mine. We offer alerts and precautions that allow you to make informed decisions and act quickly in emergency situations. We are committed to creating a safe and efficient work environment for all mining personnel. Trust the technology that drives excellence in safety. Our informative LED displays are your ally for effective communication and unparalleled risk prevention. Ensure the safety of your team and the efficiency of your operations with our advanced solutions.

- 1.- Autonomy and Clean Energy

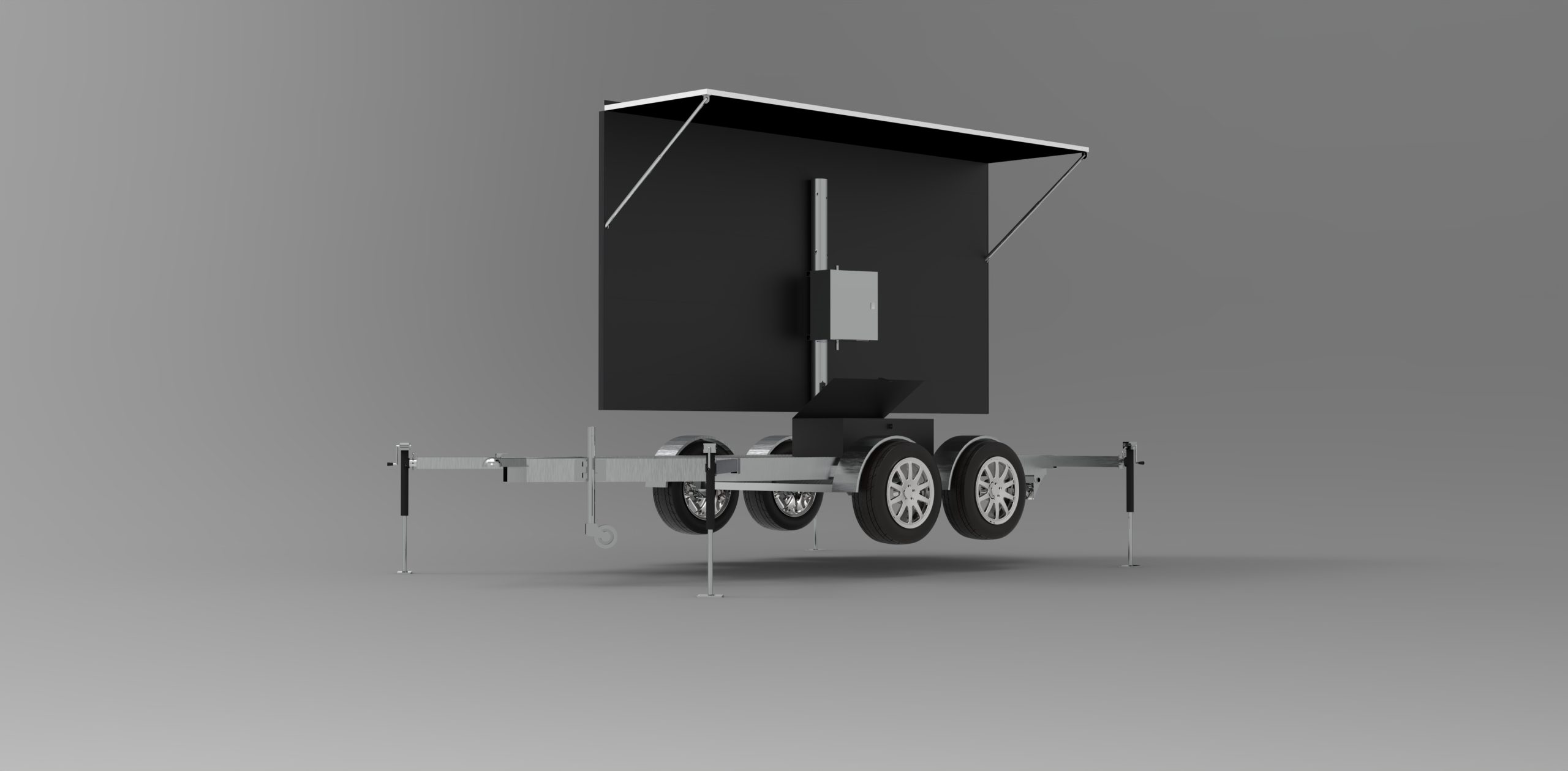

Autonomy and the use of clean energy provide efficient, sustainable and environmentally friendly solutions, contributing to the creation of a more resilient and sustainable energy future. - 2.- Easy to Transport

The Repeater Tower’s easy transportability not only expands its utility in a variety of environments, but also provides flexible and sustainable energy solutions in situations where mobility and accessibility are critical. - 3.- Complies with Mining Standards

It rigorously complies with demanding mining standards. Every aspect of its design and construction has been conceived with the commitment to meet and exceed established regulations. This not only ensures its optimal functionality in challenging mining environments, but also its full compliance with the safety and efficiency protocols governing this industry. - 4.- Electropainting Treatment

Provides superior protection and colors compared to liquid paint. It is also known as oven painting, electrocoating, powder coating, electro-enameling, and electropainting. - 5.- Hot-dip Galvanized Chassis

The hot-dip galvanizing process involves applying zinc surface coatings to iron and steel parts and elements by immersing them in baths of molten zinc at a temperature of 450°C.

Simplified equipment for hard-to-access terrains

Simplified equipment for hard-to-access terrains Features wireless connection

Features wireless connection Energy autonomy

Energy autonomy Degree of protection for extreme environments

Degree of protection for extreme environments 24/7 energy availability

24/7 energy availability Exclusive design

Exclusive design Cerbo GX monitoring system

Cerbo GX monitoring system 3×2 meters P10 LED display

3×2 meters P10 LED display Hybrid photovoltaic system, supported by alternating current

Hybrid photovoltaic system, supported by alternating current 9,600W battery bank

9,600W battery bank Allows configuration of characters and images

Allows configuration of characters and images Easy reading at 10 meters

Easy reading at 10 meters