DESCRIPTION

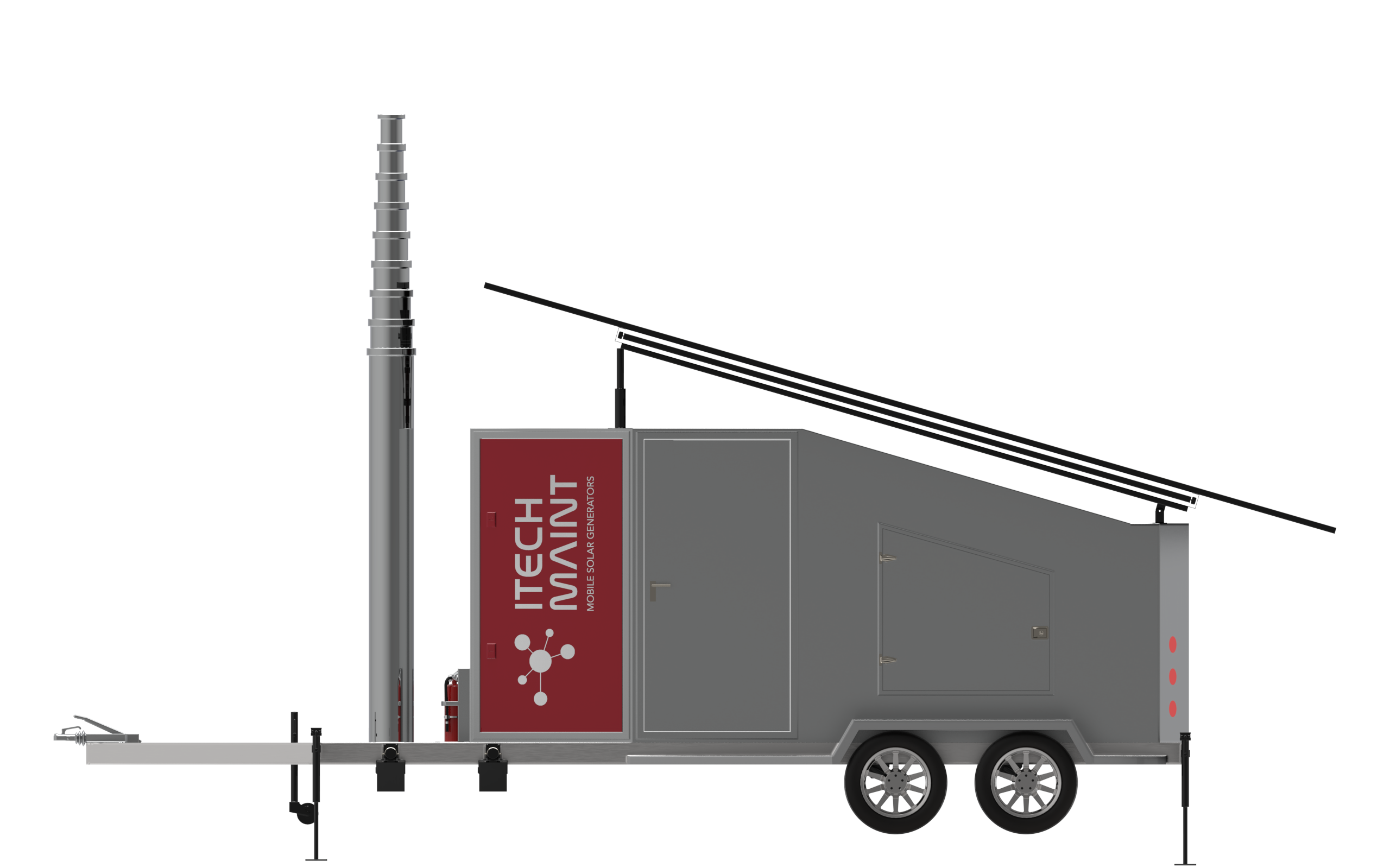

Discover the revolutionary Mobile Truck Nomade, the leading solution for demanding environments, such as open-pit mines. With an impressive power of 5,500 VA, a robust autonomy of 96,000 W and a silent generator of 12,000 VA, this vehicle stands as the reliable power source that your telecommunications and radio frequency system needs. What makes the Mobile Truck Nomade unique is its pneumatic telescopic tower, capable of rising up to 24 meters. This innovative feature provides a strategic platform for essential equipment installation, ensuring optimal coverage over vast areas. Specifically designed to face the challenges of open-pit mines, the Mobile Truck Nomade stands out for its robust construction and independent operation capability. It becomes the comprehensive solution for powering communication systems in remote and hard-to-access locations, meeting the needs of teletracking and trunked radio system. But this is not all, its design adapted for dynamic environments not only provides reliable power, but also facilitates mobility. With this innovative vehicle, we ensure stable and efficient connectivity in places where traditional infrastructure could be limited. Opt for the future of mobile power with the Mobile Truck Nomade: power, versatility and performance in one package.

- 1.- Autonomy and Clean Energy

Autonomy and the use of clean energy provide efficient, sustainable and environmentally friendly solutions, contributing to the creation of a more resilient and sustainable energy future. - 2.- Easy to Transport

The Repeater Tower’s easy transportability not only expands its utility in a variety of environments, but also provides flexible and sustainable energy solutions in situations where mobility and accessibility are critical. - 3.- Complies with Mining Standards

It rigorously complies with demanding mining standards. Every aspect of its design and construction has been conceived with the commitment to meet and exceed established regulations. This not only ensures its optimal functionality in challenging mining environments, but also its full compliance with the safety and efficiency protocols governing this industry. - 4.- Electropainting Treatment

Provides superior protection and colors compared to liquid paint. It is also known as oven painting, electrocoating, powder coating, electro-enameling, and electropainting. - 5.- Hot-dip Galvanized Chassis

The hot-dip galvanizing process involves applying zinc surface coatings to iron and steel parts and elements by immersing them in baths of molten zinc at a temperature of 450°C.

Simplified equipment for hard-to-access terrains

Simplified equipment for hard-to-access terrains Maximum safety and stabilization of telescopic tower

Maximum safety and stabilization of telescopic tower Features wireless connection

Features wireless connection Energy autonomy

Energy autonomy Degree of protection for extreme environments

Degree of protection for extreme environments 24/7 energy availability

24/7 energy availability Exclusive design

Exclusive design Monitoring system (PTZ – Dome)

Monitoring system (PTZ – Dome) Stainless steel mast

Stainless steel mast 2 RF antennas – ANT150D

2 RF antennas – ANT150D