DESCRIPTION

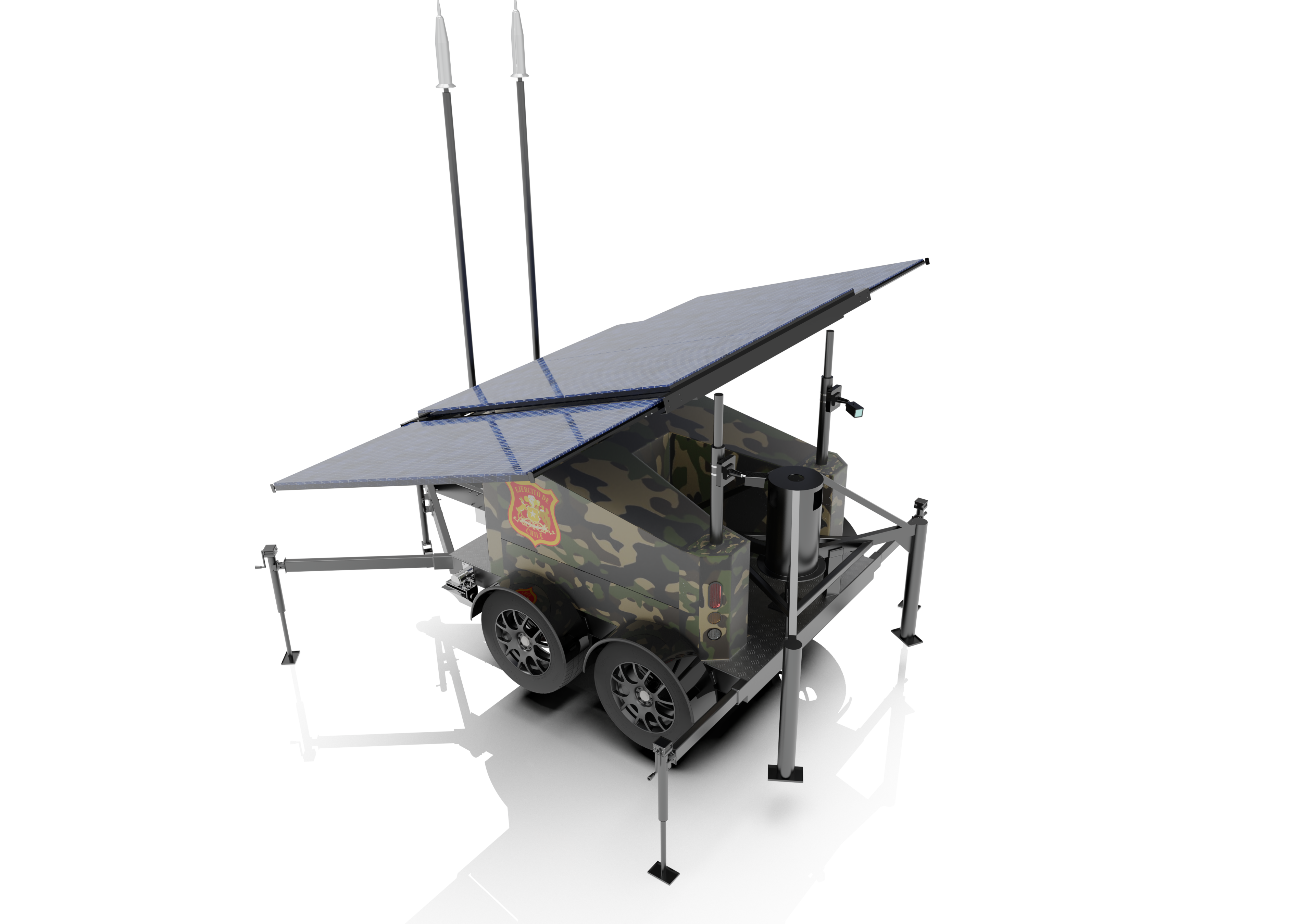

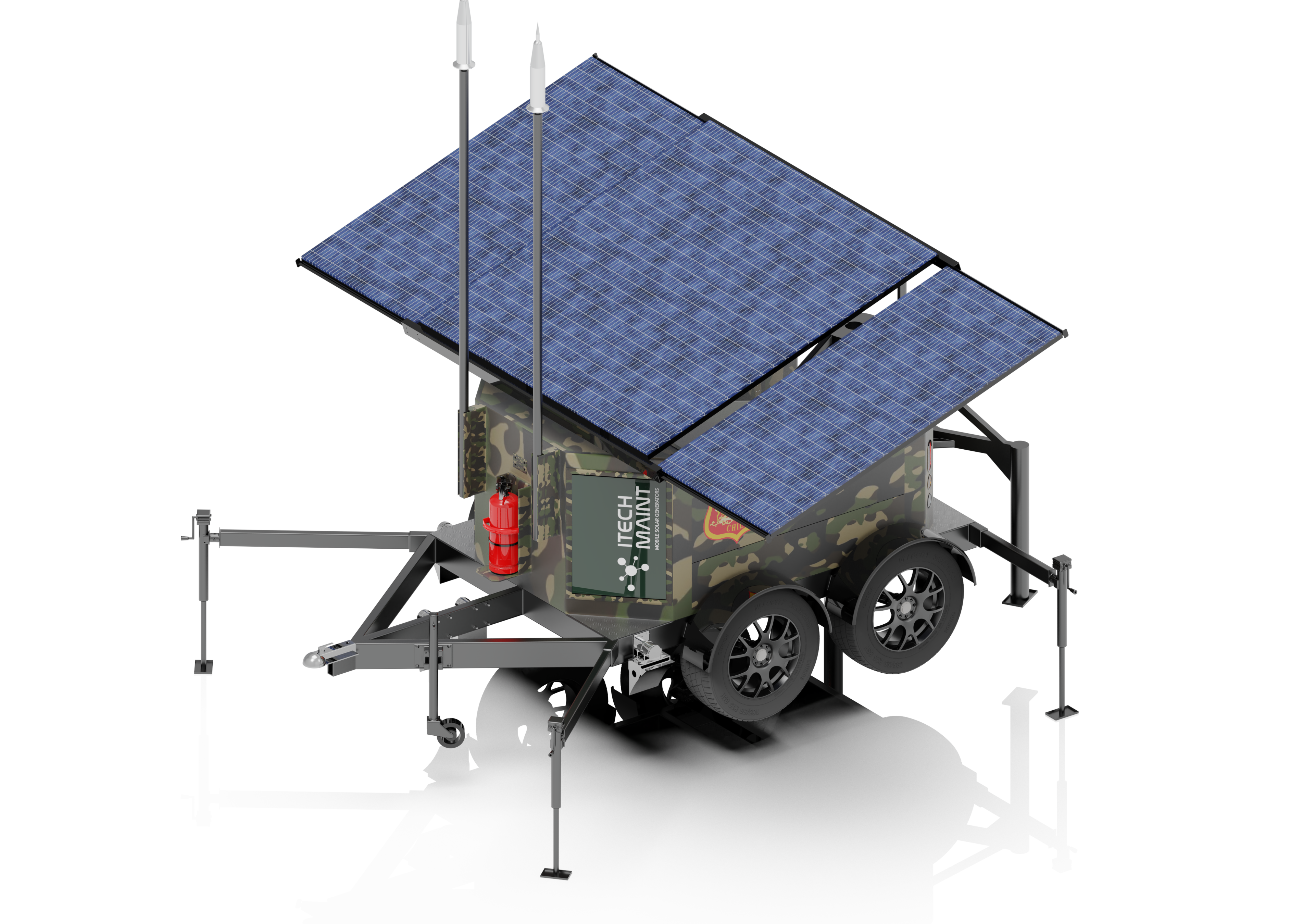

Discover the MCV9, a military radar meticulously designed to meet the specific demands of the Armed Forces. In response to the current need to control the flow of migrants through unauthorized border crossings, we are employing various solutions, and MCV9 plays a key role in this approach. Its ability to monitor, detect and alert is crucial in ensuring border security. With an impressive range of 5 to 10 kilometers, the MCV9 can identify any intrusion in the area and provide timely alerts. In addition, it is also ideal for campaigns requiring sector demarcation and absolute area control. The technology incorporated in the MCV9 reflects our commitment to excellence and efficiency in the military field, enabling more effective control of entry into our country through unauthorized borders. Itechmaint is committed to our national security with innovative and adaptive solutions like MCV9.

- 1.- Autonomy and Clean Energy

Autonomy and the use of clean energy provide efficient, sustainable and environmentally friendly solutions, contributing to the creation of a more resilient and sustainable energy future. - 2.- Easy to Transport

The Repeater Tower’s easy transportability not only expands its utility in a variety of environments, but also provides flexible and sustainable energy solutions in situations where mobility and accessibility are critical. - 3.- Complies with Mining Standards

It rigorously complies with demanding mining standards. Every aspect of its design and construction has been conceived with the commitment to meet and exceed established regulations. This not only ensures its optimal functionality in challenging mining environments, but also its full compliance with the safety and efficiency protocols governing this industry. - 4.- Electropainting Treatment

Provides superior protection and colors compared to liquid paint. It is also known as oven painting, electrocoating, powder coating, electro-enameling, and electropainting. - 5.- Hot-dip Galvanized Chassis

The hot-dip galvanizing process involves applying zinc surface coatings to iron and steel parts and elements by immersing them in baths of molten zinc at a temperature of 450°C.

Simplified equipment for hard-to-access terrains

Simplified equipment for hard-to-access terrains Tripod for radar fixation

Tripod for radar fixation Features wireless connection

Features wireless connection Energy autonomy

Energy autonomy Degree of protection for extreme environments

Degree of protection for extreme environments 24/7 energy availability

24/7 energy availability Exclusive design

Exclusive design Monitoring system (02 Bullet cameras, pointing to the radar)

Monitoring system (02 Bullet cameras, pointing to the radar) Stainless steel mast

Stainless steel mast 02 Lightning rod

02 Lightning rod Gel battery

Gel battery