DESCRIPTION

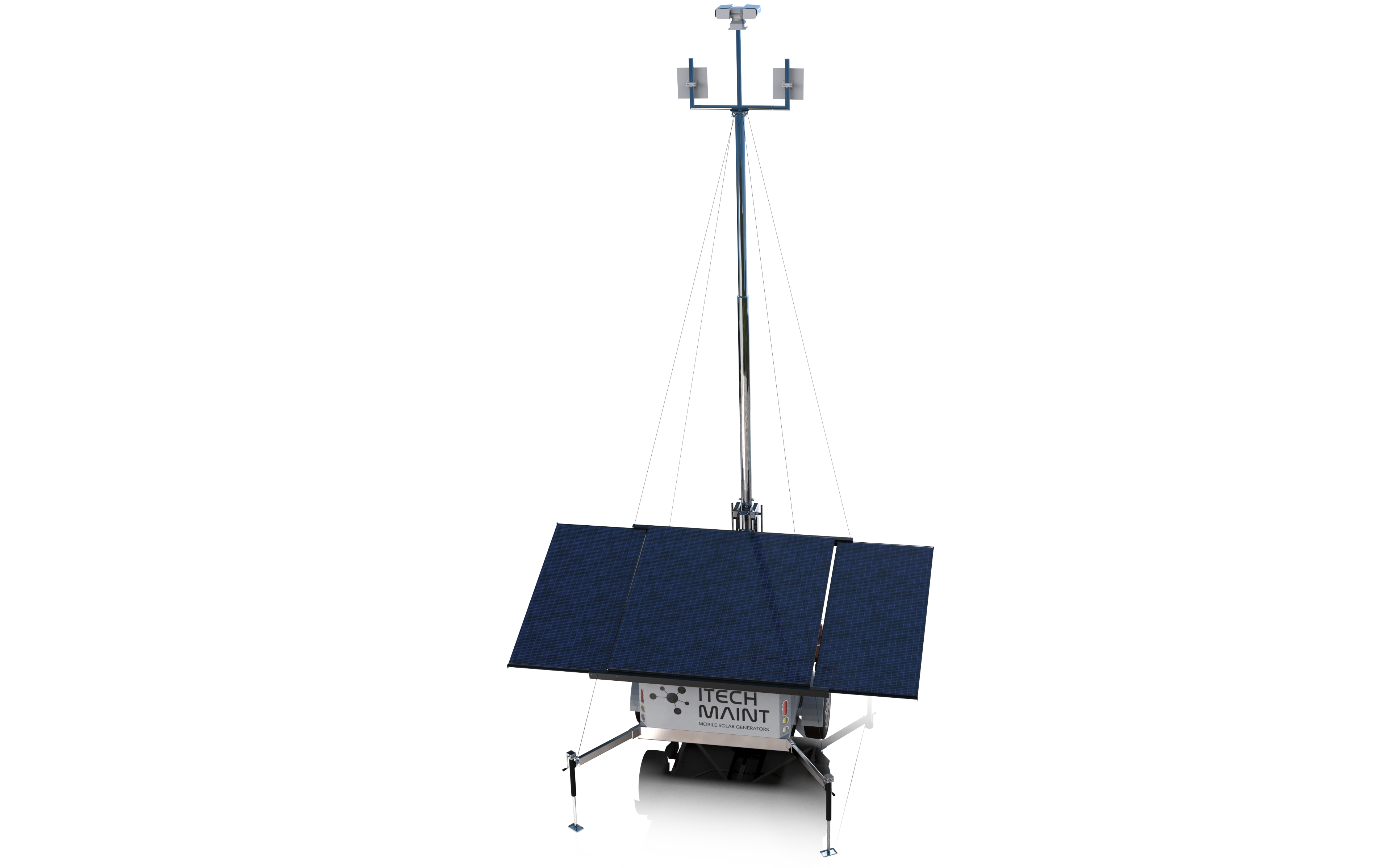

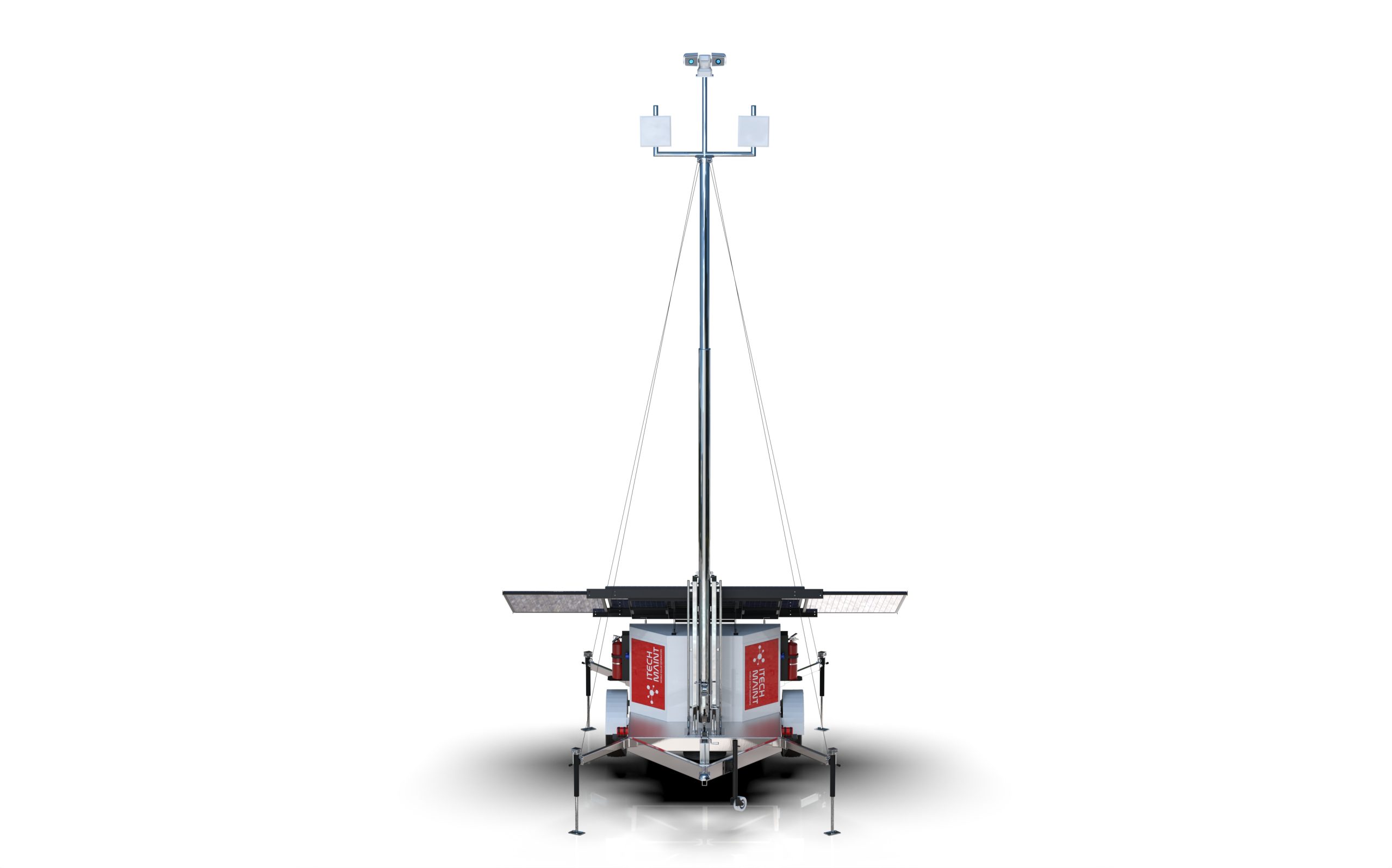

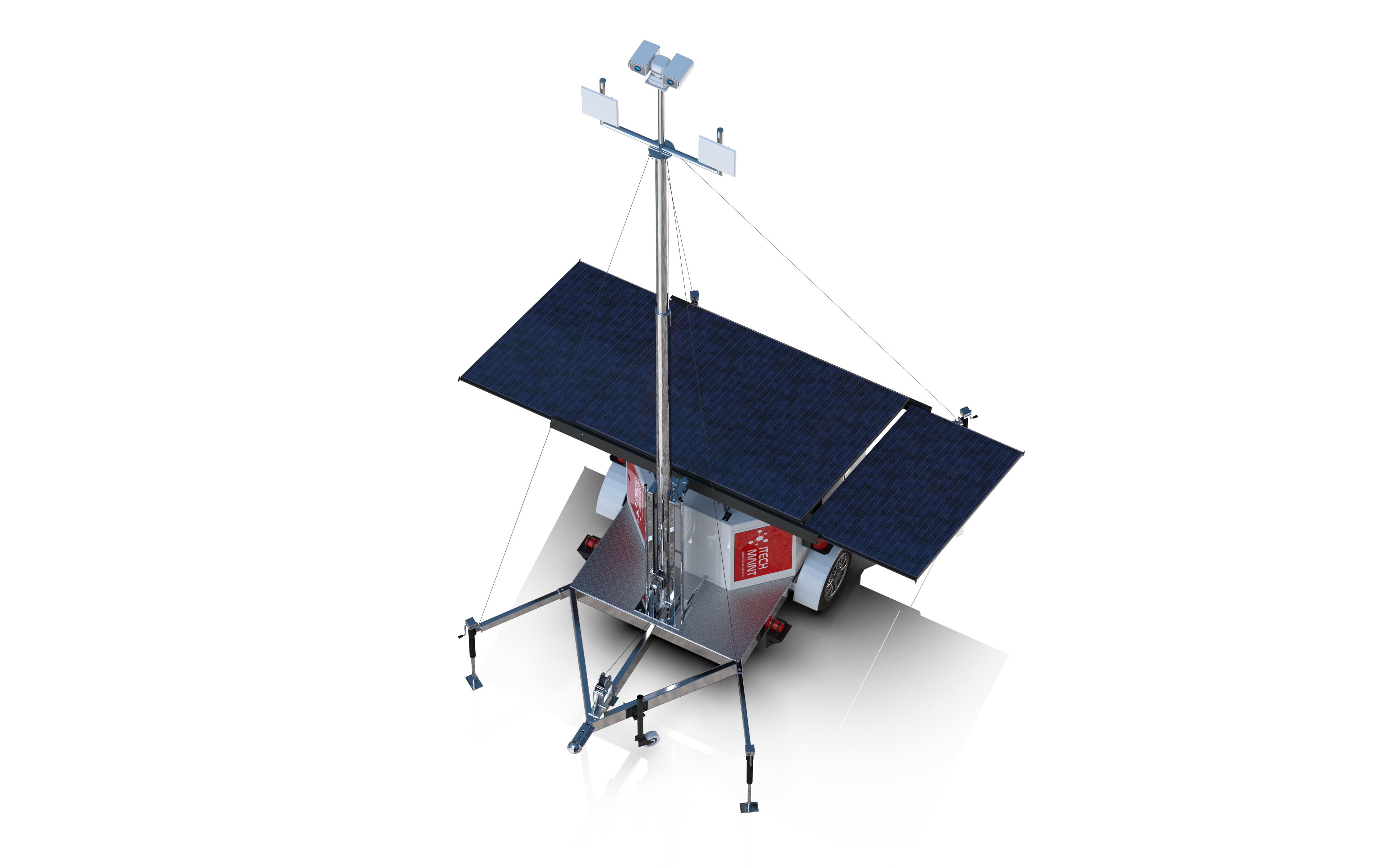

Discover the cutting-edge in energy solutions with the revolutionary Itechmaint Mobile Car V3 Generator. The Mobile Car V3 is much more than a conventional power generator. Designed to exceed the most demanding expectations, this mobile equipment is capable of generating an output power of up to 2,000 VA in AC and features storage capacity ranging from 12,000 W with 4 batteries to 24,000 W with 8 batteries. Its distinctive feature lies in its 12-meter folding telescopic tower, providing a versatile solution for connecting a variety of equipment on top, such as communication devices, cameras and lighting, among others. Experience total freedom with this innovative piece of technology; simply place the Mobile Car V3 where you need it and turn it on to enjoy instant power. There are no longer limits to your energy autonomy. If you are looking for a reliable power source and a telescopic tower to efficiently install your equipment, the V3 Mobile Car Generator is the perfect choice. Discover a new era of mobile power and versatility with Itechmaint!

- 1.- Autonomy and Clean Energy

Autonomy and the use of clean energy provide efficient, sustainable and environmentally friendly solutions, contributing to the creation of a more resilient and sustainable energy future. - 2.- Easy to Transport

The Repeater Tower’s easy transportability not only expands its utility in a variety of environments, but also provides flexible and sustainable energy solutions in situations where mobility and accessibility are critical. - 3.- Complies with Mining Standards

It rigorously complies with demanding mining standards. Every aspect of its design and construction has been conceived with the commitment to meet and exceed established regulations. This not only ensures its optimal functionality in challenging mining environments, but also its full compliance with the safety and efficiency protocols governing this industry. - 4.- Electropainting Treatment

Provides superior protection and colors compared to liquid paint. It is also known as oven painting, electrocoating, powder coating, electro-enameling, and electropainting. - 5.- Hot-dip Galvanized Chassis

The hot-dip galvanizing process involves applying zinc surface coatings to iron and steel parts and elements by immersing them in baths of molten zinc at a temperature of 450°C.

Simplified equipment for hard-to-access terrains

Simplified equipment for hard-to-access terrains Maximum safety and stabilization of telescopic tower

Maximum safety and stabilization of telescopic tower Features wireless connection

Features wireless connection Energy autonomy

Energy autonomy Degree of protection for extreme environments

Degree of protection for extreme environments 24/7 energy availability

24/7 energy availability Exclusive design

Exclusive design Monitoring system

Monitoring system Stainless steel mast

Stainless steel mast