DESCRIPTION

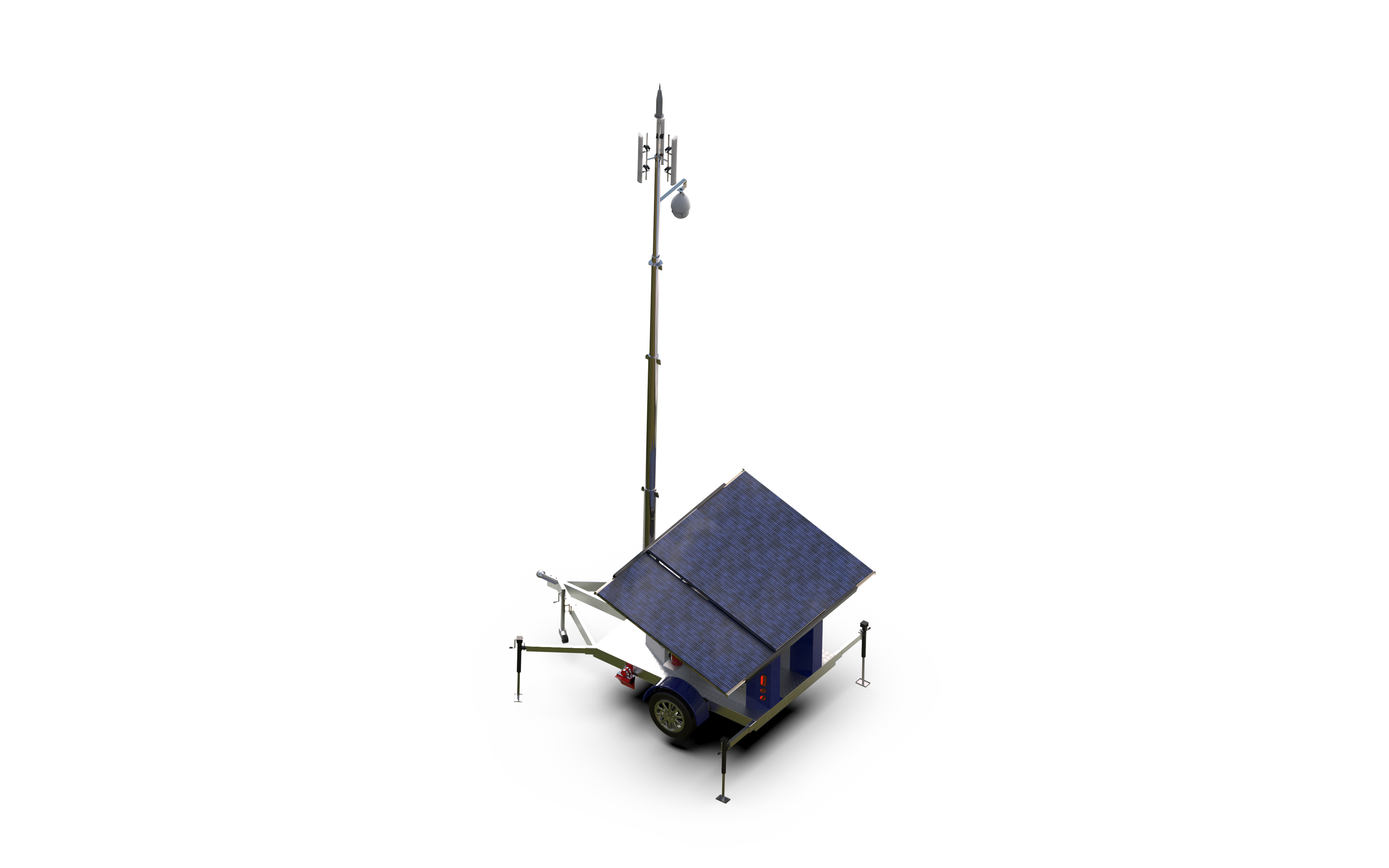

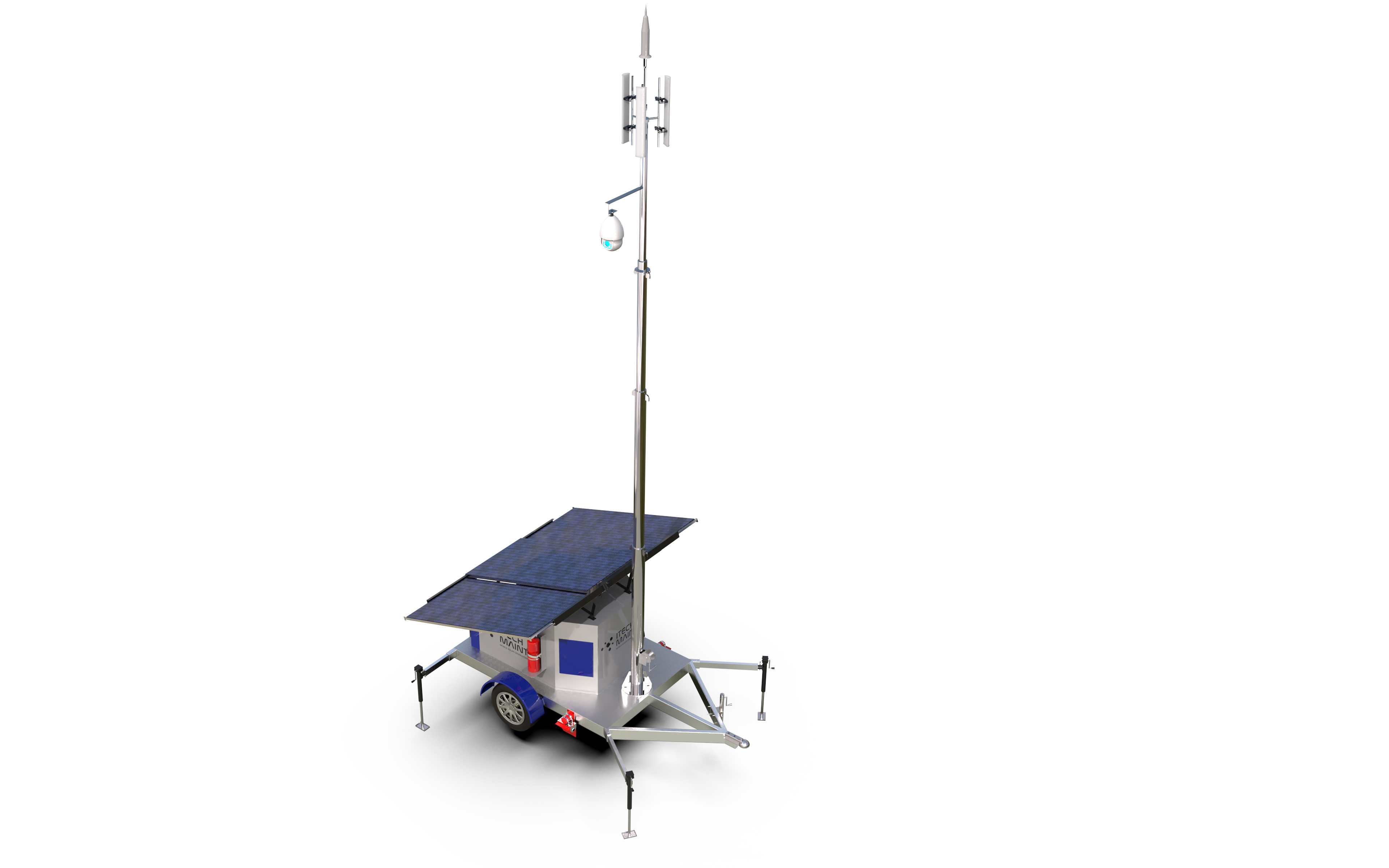

Commercial version: Discover the revolution in connectivity with the Itechmaint Repeater Tower! Designed to overcome geographic challenges in remote areas, this comprehensive technological innovation is the answer to your energy and communication needs. With an impressive capacity, the Repeater Tower works as a 1,650VA mobile photovoltaic generator, offering a 12,000W autonomy. It not only generates electric power, but also strategically stores it to supply communication antennas, keeping your connections active at all times. Equipped with a durable stainless steel mast, this tower enables you to set up, using the protocol, 802.11 a-b/g point-to-point or point-multipoint links by raising the antennas, establishing a direct line of sight with field equipment and the control room. Its unique robustness makes it perfect for hostile environments, like the Atacama Desert, being completely autonomous and easy to install thanks to its plug-and-play design. Conquer geographical limits and boost your communications with the Itechmaint Repeater Tower. The key to boundless connectivity anywhere in the world!

- 1.- Autonomy and Clean Energy

Autonomy and the use of clean energy provide efficient, sustainable and environmentally friendly solutions, contributing to the creation of a more resilient and sustainable energy future. - 2.- Easy to Transport

The Repeater Tower’s easy transportability not only expands its utility in a variety of environments, but also provides flexible and sustainable energy solutions in situations where mobility and accessibility are critical. - 3.- Complies with Mining Standards

It rigorously complies with demanding mining standards. Every aspect of its design and construction has been conceived with the commitment to meet and exceed established regulations. This not only ensures its optimal functionality in challenging mining environments, but also its full compliance with the safety and efficiency protocols governing this industry. - 4.- Electropainting Treatment

Provides superior protection and colors compared to liquid paint. It is also known as oven painting, electrocoating, powder coating, electro-enameling, and electropainting. - 5.- Hot-dip Galvanized Chassis

The hot-dip galvanizing process involves applying zinc surface coatings to iron and steel parts and elements by immersing them in baths of molten zinc at a temperature of 450°C.

Simplified equipment for hard-to-access terrains

Simplified equipment for hard-to-access terrains Maximum safety and stabilization of telescopic tower

Maximum safety and stabilization of telescopic tower Features wireless connection

Features wireless connection Energy autonomy

Energy autonomy Degree of protection for extreme environments

Degree of protection for extreme environments 24/7 energy availability

24/7 energy availability Exclusive design

Exclusive design Monitoring system (PTZ – Dome)

Monitoring system (PTZ – Dome) Stainless steel mast

Stainless steel mast