DESCRIPTION

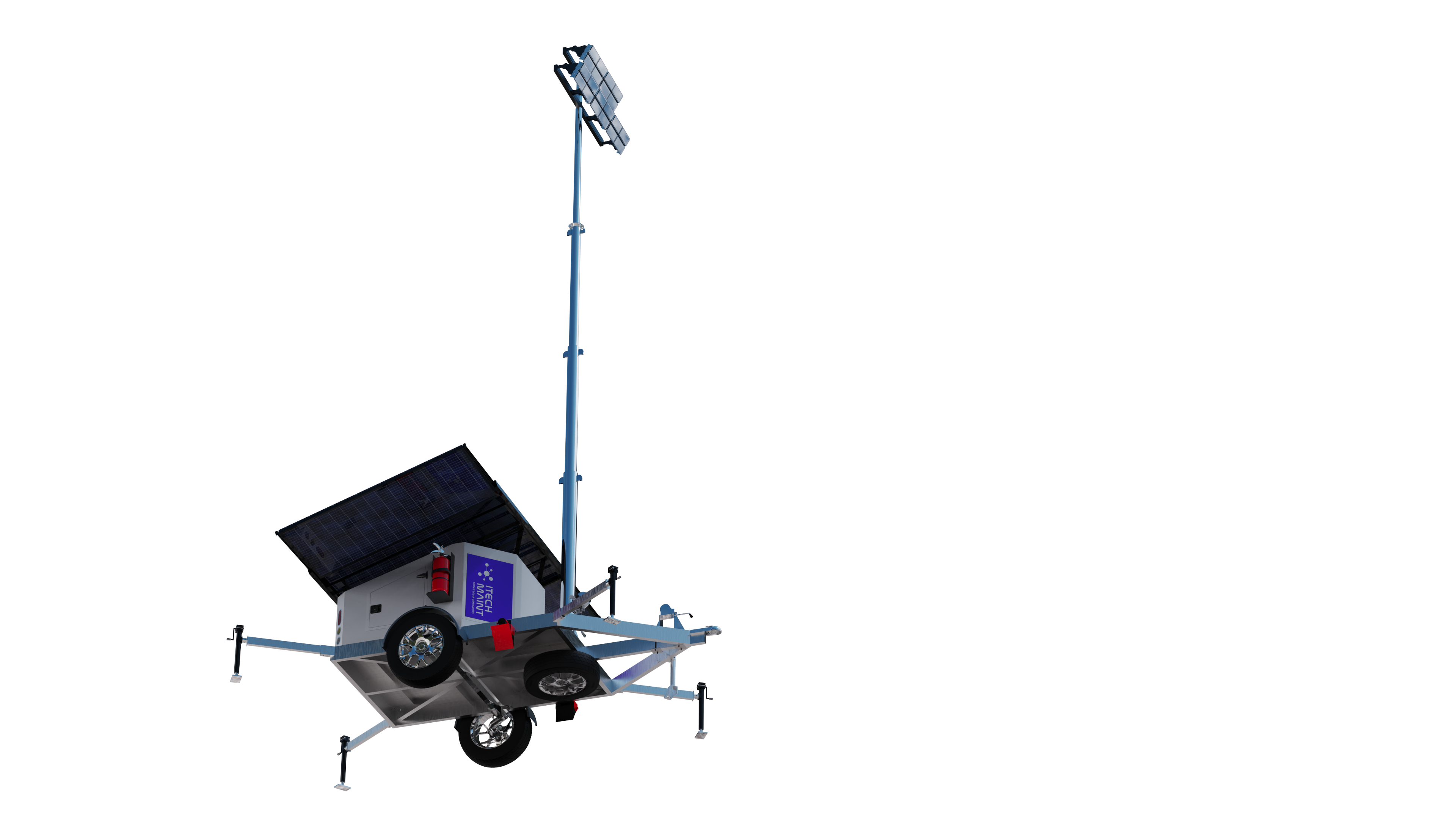

Discover the nighttime revolution with the MCV3 Lighting: your incomparable ally in operations that never rest. Designed by Itechmaint, this mobile equipment redefines night lighting in demanding work environments. With a retractable mast adaptable to various areas, from mining routes to loading and transportation fronts, the MCV3 illuminates every corner where action unfolds. Its unique ability to generate and store power makes it a versatile solution for those places where connecting to the conventional electrical grid is impossible. Offering different generation capacities and energy autonomy (2200 W), the MCV3 meets the specific technical requirements of each costumer. Its exclusive design makes it resistant to the most challenging environments, from the burning Atacama Desert to the high mountain peaks. With a 36,000 W autonomy, this equipment becomes a highly efficient solution compared to combustion generators. This technological equipment is completely autonomous; simply place it where needed and turn it on to enjoy the instant lighting as well as its remote control. Turn it on and off from wherever you are! With the MCV3 Lighting, remarkable efficiency and savings are guaranteed in every application. Increase your productivity with lighting that knows no limits.

- 1.- Autonomy and Clean Energy

Autonomy and the use of clean energy provide efficient, sustainable and environmentally friendly solutions, contributing to the creation of a more resilient and sustainable energy future. - 2.- Easy to Transport

The Repeater Tower’s easy transportability not only expands its utility in a variety of environments, but also provides flexible and sustainable energy solutions in situations where mobility and accessibility are critical. - 3.- Complies with Mining Standards

It rigorously complies with demanding mining standards. Every aspect of its design and construction has been conceived with the commitment to meet and exceed established regulations. This not only ensures its optimal functionality in challenging mining environments, but also its full compliance with the safety and efficiency protocols governing this industry. - 4.- Electropainting Treatment

Provides superior protection and colors compared to liquid paint. It is also known as oven painting, electrocoating, powder coating, electro-enameling, and electropainting. - 5.- Hot-dip Galvanized Chassis

The hot-dip galvanizing process involves applying zinc surface coatings to iron and steel parts and elements by immersing them in baths of molten zinc at a temperature of 450°C.

Simplified equipment for hard-to-access terrains

Simplified equipment for hard-to-access terrains Maximum safety and stabilization of telescopic tower

Maximum safety and stabilization of telescopic tower Features wireless connection

Features wireless connection Energy autonomy

Energy autonomy Degree of protection for extreme environments

Degree of protection for extreme environments 24/7 energy availability

24/7 energy availability Exclusive design

Exclusive design Monitoring system

Monitoring system Stainless steel mast

Stainless steel mast LED lighting – DS43

LED lighting – DS43